A while back, we wrote about the latest hot news concerning electric aircraft that were under development, and I noticed that one of them had a back-up generator as a range extender (to see that article, click here). I have friends that think a hybrid is the “worst of both worlds” but as I’ve said before concerning EV cars, I still believe that a hybrid drivetrain is a viable option for the next decade, or at least it is in some applications (to see our hybrid EV article, click here).

Well I recently began seeing lots of announcements about hybrid aircraft under development. These still have the major benefits that electric planes have, such as a much quieter take-off at small municipal airports, along with reduced exhaust emissions. Another major factor driving small electric aircraft development is the potential fuel savings, and also the maintenance costs of engine-rebuilding after it has reached its maximum safe life…since electric motors can run many more years before a rebuild. By the way, when a brushless electric motor does eventually need a rebuild, its pretty much just replacing two shaft-bearings!

It appears that the current drive to spend some effort and money on a hybrid plane is due to certain businesses wanting to get busy flying much sooner, instead of waiting any longer for certification of a pure EV plane. We recently wrote about the new developments in battery chemistry, and even though I now feel comfortable saying that the new chemistries will be here “soon”, I know that battery labs have been saying this for a decade.

And this brings us back to hybrids. Aircraft will definitely take advantage of the new batteries when they become available. You know, the ones with super-fast charging, and twice as many miles per volume. However, its pretty easy to use off-the-shelf components to create a hybrid plane, and a few companies feel that this is the path forward for their near future.

When accelerating for takeoff, a plane’s engines are run at full power. But once they begin cruising along at a level altitude, their cruise setting uses much less power. This means that when a hybrid plane has the impressive torque of an electric motor for the take-offs, the range-extending engine/generator can be much smaller than the size of engine.

Even though a big driver for these evolving changes is the effort to reduce their carbon-footprints ahead of any looming changes in regulations, these companies are genuinely excited about reduced fuel costs, and safer aircraft, due to the propulsion redundancy.

So, let’s get lookin’ at everything that’s cookin’…

__________________________________________________

VoltAero Cassio-1

I’m not a pilot, but I am fascinated by aircraft, and one of my favorite quirky airplanes is the Cessna 337 “Skymaster”. It has two engines and propellers, but they are inline, with one on the nose, and one on the rear of the fuselage “pod”. This means the tail is attached by two booms, with one on each side of the rear propeller. I liked that because if one engine stops, the plane still flies straight, instead of pulling to one side.

VoltAero is from France, and decided to develop a hybrid aircraft, and they are using a 337 as the development mule. The hybrid configuration means that every trip under 200 km can be flown as electric only (124 miles)

Their proprietary power module is installed in the aft-fuselage “pusher” position, and combines three 60-kW EMRAX electric motors (arranged in a triangular “barrel” configuration), with a 250-HP internal combustion engine. The Cassio-1 can have its aft propeller powered by either the electric motors, the engine alone, or both.

The two forward-facing propellers are each powered by a Safran ENGINEus-45 electric motor. Since the atmosphere is much cooler at high altitude, it comes as no surprise that all of the motors in this article are air-cooled inrunners, which shed heat well.

VoltAero is using the Cassio-1 to certify the powerplants in order to manufacture the 5-seat Cassio-330, and the 10-seat Cassio-600

__________________________________________________

Ampaire Electric EEL

Speaking of the Cessna 337, a company named Ampaire purchased some 337’s and swapped the front gasoline-burning Continental IO-360 engine to a Safran ENGINEus electric motor. The picture below also shows the under-fuselage pod that houses the large battery pack.

Short hops between the Hawaiian Islands have resulted in a 70% reduction in fuel consumption, and when when the gasoline engine is used as a range-extender, it has logged a 12-hour flight. Based on the success of the Electric EEL 337 prototype, Ampaire has converted a DHC-6 Twin Otter, and also a Cessna Caravan.

The pic above is the only one I could find of the 18-seat DHC-6 Twin Otter that was converted to a hybrid drivetrain by Ampaire, funded by NASA.

__________________________________________________

Airbus EcoPulse

Airbus is one of the largest aircraft manufacturers in the world, and they are a consortium of companies spread-out over several EU countries. The “EcoPulse” is based on the existing Daher TBM-910

The certification mule pictured above still retains the factory turboprop in the nose, and production models will have that engine replaced by a large battery. The wings are equipped with six electric Safran ENGINEus-50 motors and 3-pladed propellers from DUC.

Airbus is supplying the battery pack which provides 800V DC with a peak output of 350-kW of power. The range-extending series-hybrid generator is a small off-the-shelf Auxiliary Power Unit (APU) gas-turbine that burns Jet-A fuel, and it located in the tail of the craft.

The first test-flight of the electric propulsion system was in November of 2023, to an altitude of 12,500-ft.

__________________________________________________

Electra Aero’s EL-2 Goldfinch

The exceptional feature of the Goldfinch is that it has “blown flaps”. Flaps are movable surfaces on the rear edge of the main wing. By having the 8 small propellers blow air onto these angled flaps, the plane gains extra lift, and can take-off in a very short 150 feet (half a football field). Once the plane has taken off, it retracts the flaps to reduce drag.

Electra Aero is based in Manassas Virginia, USA.

The US Air Force has awarded $85-Million to EA to further develop more aircraft, due to the demonstrators quiet operation and low heat signature when flying at night, along with its short-takeoff ability.

Safran has signed an agreement with Electra to develop the 600-kW hybrid-electric turbogenerator propulsion system for the prototype of Electra’s larger nine-passenger hybrid-electric short takeoff and landing (eSTOL) aircraft.

“We have been overwhelmed by the market reception to this,” says CEO Langford. “The customer response has proven that the market is there commercially. We have over 2,000 orders without even trying…“

___________________________________________________

Elroy Air C1 “Chaparral”

The current conflict in Ukraine has shown that unmanned drones are a growing field. The US military already has a wide range of drones for every application. One of the ways that an electric drivetrain can be useful in combat is to be able to run “cool”, to avoid small heat-seeking missiles, which typically hone-in on an engines hot exhaust. However, a pure electric drivetrain does not always have enough range to accomplish certain vital combat missions. Because of this, a hybrid propulsion is getting a closer look, with Elroy Air receiving additional funding from the US Army and also the Air Force.

The C1 “Chaparral” has a detachable cargo pod, and although cargo can be in a variety of sizes and shapes, I couldn’t help but to notice that this cargo pod is also sized to be able to carry a person who needs to be evacuated. The C1 uses a vertical-lift capability, and also has forward-facing propellers to enhance range by using a conventional wing.

The C1 is a series-hybrid, where all of the redundant propulsion components are electric-only, but the range-extender is a fuel-powered generator that can be turned-on as needed.

___________________________________________________

Comco Ikarus C42/CS “Elektro”

Back in 2020, we wrote about new developments in electric aircraft (to see that article click here). One of them had a series-hybrid range-extending generator, which allowed the craft to have very quiet electric-only takeoffs, improved fuel economy, reduced exhaust, while still having a greater range than an electric-only battery pack.

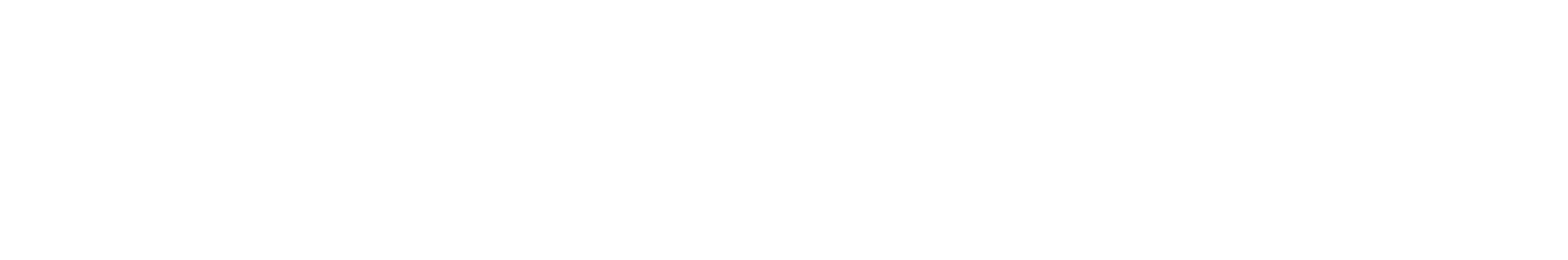

The pic above shows the propeller attached directly to an electric motor, eliminating any PSRU gear-reduction belt, which would convert the optimum engine RPM to produce the optimum propeller RPM. Motors can have their coils wound to provide any RPM that is found to be the optimum speed. This pic also shows the battery and controller configured as a module to replace commonly-found engines that are typically used on small private aircraft.

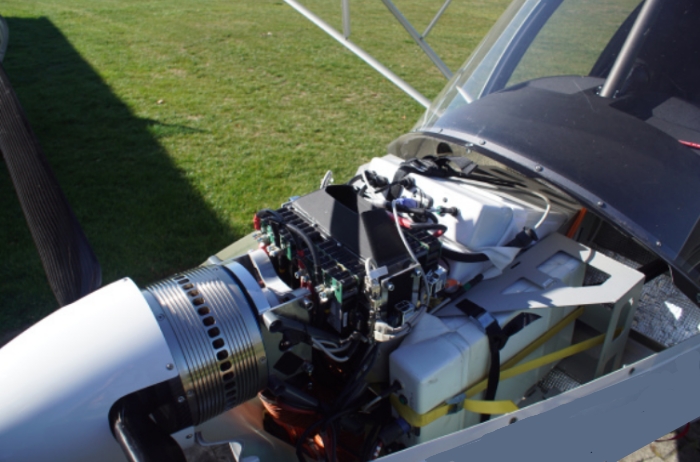

The latest group of hybrid aircraft are using APU turbogenerators, but four years ago the Comco Ikarus Elektro chose a single-cylinder 4-stroke from Helvenco, called the Aero-1000

__________________________________________________

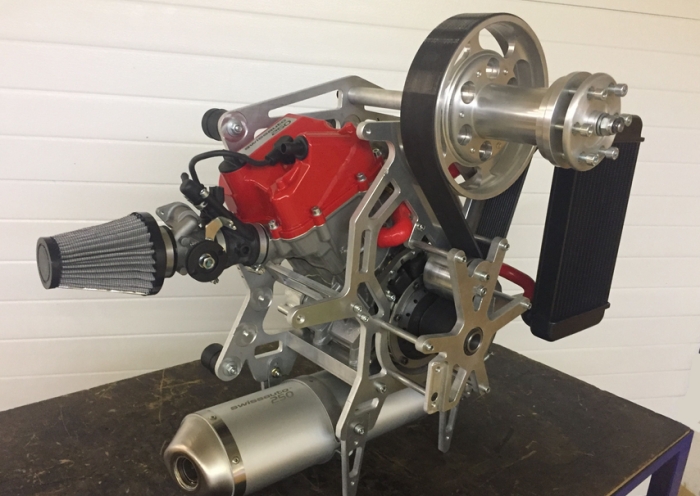

Diamond Aircraft DA36 “E-Star“

The E-Star is listed as having two seat in a fore/aft “tandem” arrangement. The propeller drive is a Siemens 70-kW electric motor, which draws power from a battery, with range-extending series-hybrid power being generated by a small 30-kW Austro Engines Wankel rotary engine and generator.

It was developed from the existing Diamond Aircraft’s HK36 Super Dimona, which is listed as a self-launching “motor glider”

___________________________________________________

Pipestrel Panthera

Pipistrel is from Slovenia, which is a member of the European Union, and their Panthera model is an existing sleek 4-seater. Recently, they have converted one of them to a hybrid drivetrain.

The stock engine is the gasoline-powered Lycoming IO-540, and they have stated that their main interest in the hybrid drivetrain is that the electric portion allows them to meet carbon-footprint reduction goals, while still allowing the series-hybrid range-extender to be flexible in design, taking into consideration the rapid changes in these components, and evolving regulations.

___________________________________________________

Tecnam P2010 HP3S

The Italian company Tecnam has successfully flown a hybrid version of its existing P2010.

The Tecnam P2010 “H3PS” is powered by a 104-kW Rotax 915 IS engine coupled with a 30-kW Rolls-Royce electric motor, totaling 134kW (180hp), and can bear the same useful load of the traditional 180-HP combustion engine. The hybrid powerplant replaces the larger stock Lycoming O-360 piston engine.

___________________________________________________

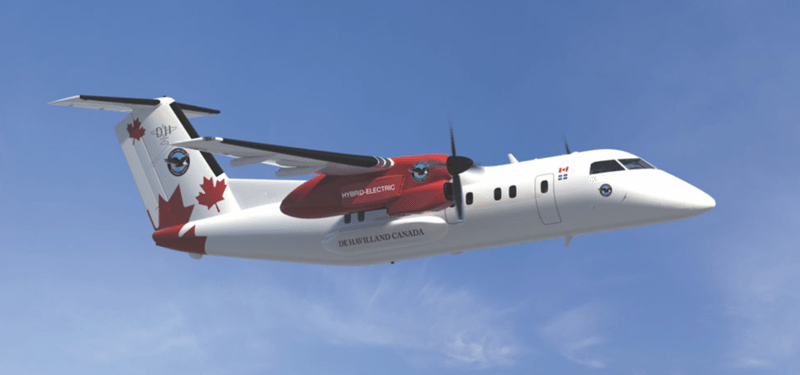

United Technologies DH Dash 8-100

Pratt & Whitney Canada is developing a parallel-hybrid electric version of the De Havilland Dash 8-100, a 37-seater turboprop aircraft commonly used to serve regional routes. The two standard engines are the P&W-120 turboprops.

By adding electric motors to assist with take-offs, P&W was able to maintain the expected performance while switching to smaller engines, allowing for a 30% improvement in fuel consumption, and a significant reduction of emissions. The 800V battery has been supplied by Swiss supplier “H55”

The popular DH Dash 8-100 was designed in 1984, and is still in production today.

___________________________________________________

Surf Air Mobility

Surf Air Global Ltd is a British Virgin Islands corporation doing business as Surf Air Mobility (SAM) with their headquarters in Hawthorne, California. SAM has contracted to purchase 100 of Textron Aviation’s Hybrid Cessna Grand Caravan aircraft, with an option for 50 more.

Jetstream Aviation has expressed its intent to purchase up to 250 hybrid-electric powertrains from SAM over the course of the next five years. The planes will be fitted with hybrid electric powertrains produced by SAM’s Ampaire division.

___________________________________________________

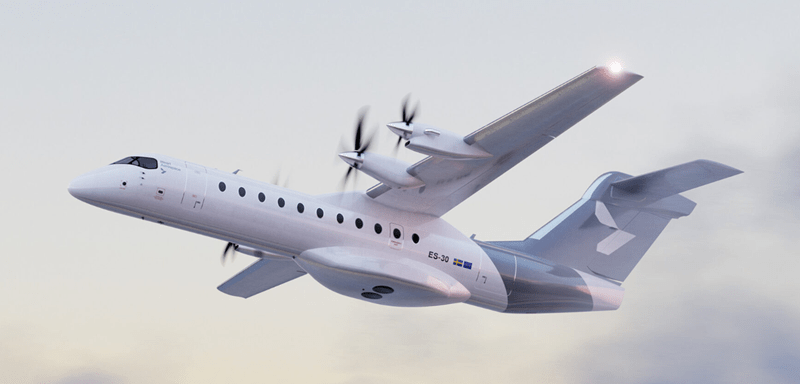

Heart Aerospace ES-30

Swedish company Heart Aerospace and regional airline Loganair are developing use-cases for hybrid-electric aircraft in the UK. Heart Aerospace is developing the ES-30 hybrid-electric aircraft to have a capacity of 30 passengers, a fully-electric range of 200km (125 miles), and an extended hybrid range of 400km (250 miles). Heart Aerospace has a total of 250 firm orders for the ES-30

___________________________________________________

APU’s

The Honeywell RE100 APU below is typical of a small “Aircraft Power Unit”, and its size is 520mm x 360mm (21 x 14 inches), and of course APU’s are available in larger sizes, too. It uses a small gas-turbine “jet engine” that is similar in construction to a turbocharger impellor, and it converts a Jet-A fueled flame into a spinning shaft, which then turns a generator that can have its coils wound to provide any voltage that is needed.

The APU shown above is typical of aircraft generators. It uses a spinning turbine, which has been proven to reliably run many thousands of operational hours, compared to a piston-generator.

___________________________________________________

There are many more hybrid aircraft under development than the ones I have listed here, but I don’t like posting a CGI graphic if its the only image available. I prefer pictures of actual aircraft. I only hoped to convey that hybrid and electric aircraft are both being aggressively pursued in real life. Battery improvements have been disappointingly slow, but all indicators show that they actually are about to make a big splash soon, as we listed about CATL developments here, and also with silicon anodes here.

Electric/hybrid aircraft are the most demanding application for batteries, and this industry has a fat wallet that they will gladly spend on actual improvements, so this is a good industry to keep an eye on…

___________________________________________________

Written by Ron/spinningmagnets, November 2024

.

.

.

#HybridElectric #Aircraft

Source link