Kevin lives in a very hilly part of Georgia, and he just completed this conversion of a Suzuki DR650 from gas to electric. That by itself is really cool, but the thing that stands out about this build is that he put a lot of effort into being able to retain the stock 5-speed gearbox, which is amazing. So…let’s take a look!

_____________________________________________

I’ll start by posting a transcript here, of Kevin’s details from his youtube video…

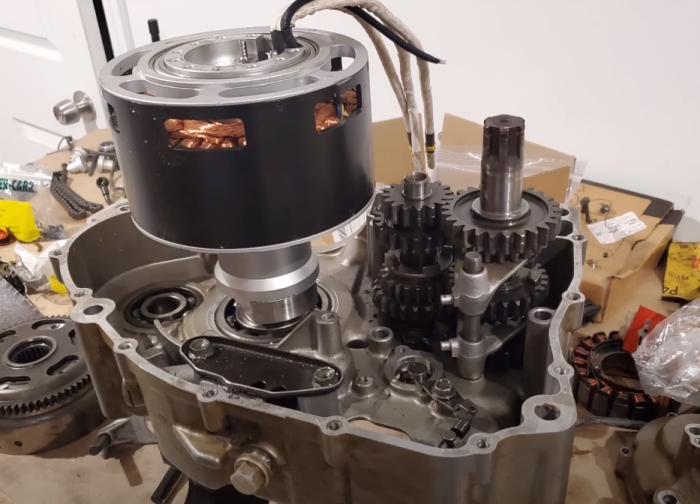

“What’s up Youtube. I’ve been building this bike for about two years. Started with an RC outrunner motor, inside the case of the stock bikes transmission…and, uh…I could never really get that working right with the ASI BAC8000 controller, so I decided to switch the motor to a QS 138/90H. It’s also inside the case.

Later in the video, I’m going to show you how I got all that to fit, with some pictures and stuff I took along the way. But, just spent all weekend getting this thing buttoned up. Like I said for the last two years, it’s [now] out of my garage. So, trying to program the BAC8000 [controller], I have a love/hate with, but…it’s working now so…I guess I’m loving it now. I’m actually finding the controller quite fun to program, now that I’ve made some headway with it and started to understand it a little better.

It runs two Kia Soul EV modules, which are 10S each (36V), so it’s a 20S pack (72V), so two of those modules in series. I haven’t wired in the BMS yet, so this charge cable will go, but it’s hanging on there so I can charge it a little bit. [You] might be wondering what this gauge is for. This is actually the oil pressure gauge, because there’s a lot of modifications to the oil system on this…because the whole top of the engine isn’t there anymore.

So, I wanted to make sure I was getting proper oil pressure. It’s also the cooling system for the clutch, the electric motor (the QS 138 is now oil-cooled), and it flows through the transmission as well, so…gotta make sure that oil’s flowing.

So you can see a little bit about how it works here. I re-plumbed the stock oil system, so these oil lines go back to an oil cooler that’s up in the back of the bike. [I’ll] probably add a fan to it…it’s picking up a lot of heat, so…put a fan on that later.

And anyway, so the oil circulates back through the oil-cooler to the front to this manifold block where it’s distributed out to things like the pressure gauge, to the transmission, and in the future, to a couple more oil-sprayers I’m going to install around the motor. There’s also a large bypass valve in-between the two batteries that you can’t see with the bike assembled, so I’ll show you a slide of that later on.

Just got the lighting rigged-up today. It’s got turn signals, headlight, tail-light…so that’s exciting. It makes it more enjoyable on the street, for sure. It’s got a brake light too. Yeah, that’s about it. I’m going to show you some clips of it ripping and probably put some pictures in of the parts I made.

Feel free to ask any questions in the comments below. Thank you.

“How fast does this thing go?”

60-MPH (96 km/h)…in the future I’m going to be able to increase the motor RPM’s with field weakening up to around 5,000-RPM’s (from 4,000-RPM’s), and I’m also going to drop the rear sprocket down some teeth to probably around 35T (from 42T). This is going to require a custom billet adapter to the cush-drive, which I’m gonna make in a future video. But, you can see [in the graph], this really spreads out my gear ratios, and makes everything much more useful.

In the last week of riding, or so, I find myself in fifth-gear all the time…which will become the new third-gear, and that will give me an increased top-speed in the fourth and fifth gears, as well as the capability of getting out on the highway for an exit or two between stops. So, I hope that helps on the top-speed question.

I look forward to seeing what it will actually achieve when it’s geared properly.

“What is the range, how far will this bike go?”

It will go about 40 to 50 miles of range, based on my miles-per-kilowatt-hour that I’m recording right now.

“Why did I need a gearbox?”

I live in Northern Georgia, and it’s super hilly here. I’ve done a couple single-speed builds before, and one thing I’ve found with single-speeds is I’m always wanting a different gear ratio. In the hilly mountainous areas, I want something shorter, and on the road where it’s flat and open, I want something taller. And I just could never settle on a [single-speed] gear ratio.

So, I figured with a gearbox, I could quickly click into the gear that I want for the situation I’m in, and have a lot of fun with it. It also adds like…a ton of fun factor to riding the bike. I’m a manual transmission guy in general, I buy only manual transmission cars and vehicles.

And, It gives me that solid feel with a modern bike with the electric drive. So overall I like the fun factor of driving a manual on an electric motor, or a gas motor, box truck, sports car, whatever…as long as it’s a manual, I like it.

“Future plans?”

So, this is specifically cosmetic. So, a lot of people commented on the looks of the bike. Some people loved it, some people hated it. Either way, I think everyone was right in this case, there’s some things that look really good and, somethings that look yeah, really bad. So, I do plan on doing a whole cosmetic restoration of the bike, as well. I wanted to get the mechanical fundamentals set-up first. Next will be a resto on the cosmetics.

Scrambler style is what I’m going for. So, round headlight, cut the tail down a little bit (pic at 3:38), and then I’m going to make some carbon fiber trim pieces for the side panels, and the gas tank. I’ve done carbon fiber body stuff in the past. So…I’m looking forward to a new carbon-fiber project.

And, uh…we’ll do a video about how you make carbon-fiber parts, and maybe I’ll do a 3D-printed mould even, so…look for that in the future.

“What’s next for the series on the DR650?”

I’m planning on doing a few more videos on the DR650. I want to do the next video on the design and the build of the bike, so let’s go over the CAD-design (Computer Aided Design), programming, and CNC set-up, fabrication of the parts, that sort of thing. We’ll do that one next, probably.

Then I want to do a video on the total cost analysis, about costs to build a project like this, and how much of the money gets diverted into the machine itself, verses how much of it gets diverted into tooling that you can use for future projects. I think that’ll be fun.

And then I want to do a video on tuning the ASI [BAC8000] controller, which…is…actually really fun to get to know it a little bit. But in the beginning, it’s very daunting, and…ASI refuses to open up their support to the public, which…you know…is, I get it with this model, but…I built my entire career building sales and marketing programs for technology companies, and…I…can’t really understand what they are doing. So, um, if you want any advice, ASI…I’m happy to help.

And then I think I want to do a video on the restoration of the bike itself, but that would be in the future, because it’s going to be a longer process. Very detail oriented. Painting, powder-coating, etc, so…

That would be in the future, only enjoy the bike for the summer…probably do that in the winter. So, yeah, little bit in the future. And the last thing I want to talk about in this video is this channel and what we can do on this channel, so…

You might have already seen I sell programs. That’s what I’ve done professionally my entire career. I work in advanced manufacturing. Taking…taking…products like CAD software, or 3D-printers, analysis CT scanning machines, and software for CT scanning machines to market…and, um…I want to mix some of that flair into this channel, so…I know I want to build stuff, but I think I also want to cover the businesses that supply the machines and the components that go into these builds.

I’d like to know if you think that’s interesting, if you think that will make this channel unique. I’d love to hear your thought on anything else you’d like to see, I mean, I think it would be pretty reasonable to interview engineers who design machines and parts that go into these builds.

I think it’s also feasible to visit some vendors that supply, you know, manufacturing machines…or, the parts that go into the builds, so…I think all that’s pretty reasonable. I have a relatively broad network in that manufacturing space, and I think we can come up with some places to go visit. That might be interesting, so…Let me hear your thoughts on where you’d like to see the channel go, and I might be able to try to implement as much of that as I possibly can.

Again, thank you so much for watching, and see you next time.

Here is the 7-minute build and ride video…enjoy!

_____________________________________________

Our take on this

I am happy to see more builds using hybrid cells from a hybrid EV wreck. Pure EV’s have a huge battery, so they can easily provide huge amps, simply due to the physical size of the pack. this means the designers are free to spec cells that are optimized for long range.

A hybrid car is a little different. Since it has an on-board engine, it is not concerned with range (A hybrid Chevy Volt can typically drive only 80 miles in electric-only mode, while the Tesla Model-S can easily do over 300 miles). This means the expensive battery can be much smaller. HOWEVER!….this small battery pack must be able to propel the heavy car by itself on occasion, so the cells are the “high amp” cells we love (click here)…

Motorcycles need high amps to provide great performance without the cells getting hot, and they must do that with a small pack that can fit in a tight motorcycle frame.

_____________________________________________

Transmissions on an EV?

If you are designing an electric motorcycle from scratch, in order to sell them to the public…there are several good reasons to choose a large motor with no transmission, vs a smaller motor with some gears. The most successful electric motorcycle company is the Zero, by far. However…they use 28 cells in series (28S) which is roughly 104V nominal.

Kevin is using a more available and affordable 20S / 72V battery, so he is starting off with less power. On top of that, his user-profile is for a dual-use enduro. It’s main job is crawling up steep terrain of a widely varying grade, but once in a while…it would be useful for him to take a quick shot down a paved road at highway speeds. Accomplishing that with only 72V is a tall order.

If he had no transmission, the steep portion of the ride would suck down very high amps, which causes lots of heat in the motor, controller, and battery…and also shortens his range. Then, his top-speed on the streets would be compromised if he chose a sprocket-set that was lower-enough to run off-road well.

One of the benefits of an electric drivetrain is the incredible torque that is available down low at the first RPM. But…there are still limits. If you want to build an electric motorcycle conversion that is either “street only” or “off-road only”, there are existing configurations that will do that with no transmission, making the resulting motorcycle simpler to convert, and also leaving more frame-room for a larger battery pack.

However, if you want to have an enduro that can work well for a dual use (dirt and street), then I would humbly suggest that dozens of builds have proven time and again that having two widely-spaced gears is the absolute minimum to pull that off (and I believe that three gears is close to ideal).

Kevin didn’t “choose” 5-speeds. He already owned the Suzuki for a long time and then the engine died. He decided to convert it, and it just came with the 5-speed. In fact, he specifically mentioned that he spends most of his time in 5th gear. It was just lucky that this large 650cc single cylinder had an enormous crankshaft and counter-weight, and as a result he was able to remove them and fit the QS 138/90H inside the case (after shaving all the parts!).

Here is our recent article on the Denzel “motor and 4-speed gearbox” (click here). And here’s our article on bicycle multi-speed IGH transmissions (click here). Once you understand how the vintage 3-speed internally-geared Hubs work, you can see that there is no reason they couldn’t be scaled-up to motorcycle size. I know I will sound nuts for saying this, but the Ford Model-T from the 1910’s had a “planetary gear” transmission that was a very compact and robust unit. It had two forward speeds, a neutral, and one speed in reverse (sometimes listed as a 3-speed). Something like that would be a great option for an electric enduro…

For those who are curious about the QS cylindrical motors, here is our article on them (click here).

_____________________________________________

Written by Ron/spinningmagnets, July 2021

Source link