.

.

.

#GearboxBikes #EbikeInnovation #IntradriveGD8 #SustainableBiking #EbikeTech #NextGenEbikes #BulletProofGearbox #ScotlandMade #EbikePerformance #LowMaintenanceBiking #EbikeDrivetrains #EbikeFuture #MotorGearbox #EbikeRevolution #PremiumEbikes

Source link

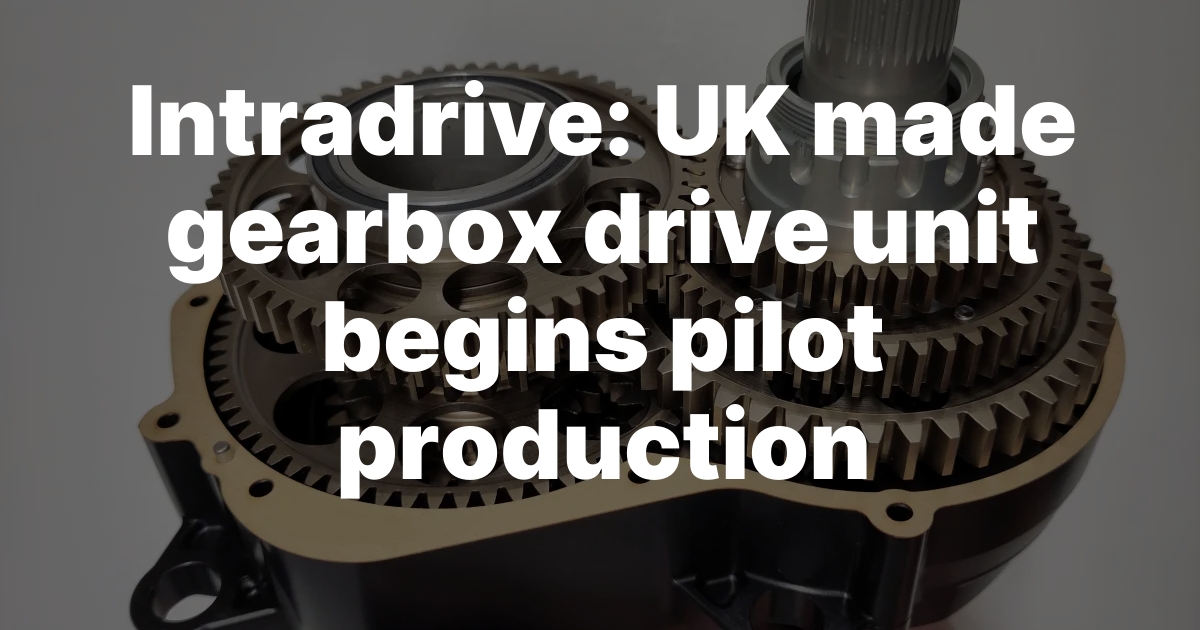

Intradrive, a UK-based company, has unveiled the production-ready version of its GD8 gearbox drive unit, signaling a significant advancement in e-bike technology. The GD8 integrates an eight-speed gearbox and a powerful motor into a single, compact unit, eliminating the need for traditional derailleur systems. Designed with durability, performance, and repairability in mind, the GD8 aims to revolutionize the e-bike market by offering a low-maintenance, high-performance alternative to conventional drivetrains.

Manufactured in Edinburgh, Scotland, the GD8 is engineered to fit seamlessly into the same frame space as the widely-used Shimano EP8 motor, making it a viable option for existing Shimano-powered bike owners. This compatibility, combined with its sleek design, allows for clean integration with modern e-bikes, catering to both urban and off-road enthusiasts. The GD8 also offers the option of either chain or belt drive, providing flexibility for different riding styles and preferences.

The production model of the GD8 introduces several key improvements over its prototype predecessor. These include a more compact design for better integration, enhanced motor efficiency with a higher copper fill factor for improved power delivery, and refined shifting mechanics for smoother gear changes, even under load. These advancements highlight Intradrive’s commitment to delivering a premium user experience characterized by reliability and performance.

Mark Ravilious, Founder of Intradrive, emphasized the game-changing nature of the GD8, noting that it addresses the frustrations of riders with traditional derailleur systems. “The GD8 represents a significant step forward in e-bike drivetrain technology,” he stated. “By eliminating derailleur systems, we’re offering a drivetrain that reduces maintenance, improves reliability, and enhances the overall rider experience.”

Peter Slotwinski, Co-Founder, highlighted the challenges of developing cutting-edge technology on a limited budget. Supported by Scottish Enterprise, Intradrive has successfully industrialized the GD8 and is now ready to deliver pilot units to leading bike brands for testing. Slotwinski expressed confidence in the GD8’s potential to meet the growing demand for high-performance, low-maintenance e-bike technology.

Intradrive’s manufacturing process incorporates state-of-the-art equipment and rigorous quality control measures to ensure consistent production standards. The company has invested in production tooling and partnerships with European manufacturers known for their advanced quality control processes. Additionally, Intradrive conducts in-house quality checks and end-of-line testing to maintain reliability as production scales.

The global e-bike market is projected to surpass $200 billion by 2035, and Intradrive believes the GD8 is uniquely positioned to capture a share of this premium segment. The company is actively seeking investment to scale production and meet growing demand. Intradrive is also open to strategic partnerships with OEMs that share its vision of advancing e-bike technology and promoting sustainability.

Sustainability is a core tenet of Intradrive’s mission. The GD8 is designed with circular economy principles in mind, prioritizing repairability, durability, and reduced waste. By creating a product that is both high-performing and environmentally friendly, Intradrive aims to support a more sustainable future for the cycling industry.

Founded by engineers and lifelong cyclists, Intradrive’s team brings a wealth of experience from downhill and enduro racing, cycle commuting, and cargo bike transport. This diverse background has informed the development of the GD8, ensuring that it meets the performance demands of e-bike users while addressing the shortcomings of traditional technologies.

With pilot production now underway, the first batch of GD8 units is set for delivery to leading bike brands for testing. These units are manufactured using production tooling and an integrated process to maintain consistent quality. Intradrive’s goal is to deliver a drivetrain that not only reduces maintenance but also enhances the overall user experience, delivering a premium feel and performance.

In summary, Intradrive’s GD8 gearbox drive unit represents a significant leap forward in e-bike technology. By integrating an eight-speed gearbox and motor into a compact, durable, and repairable unit, the GD8 eliminates the fragility and maintenance associated with derailleur systems. With its focus on sustainability, performance, and reliability, the GD8 is poised to make a lasting impact on the e-bike market, offering riders a high-performance alternative that aligns with the demands of a rapidly growing industry. For more information, visit www.intra-drive.com or follow @intra_drive_ltd on Instagram.