Some links may be affiliate links. We may get paid if you buy something or take an action after clicking one of these.

You’ve no doubt seen references to geared hub motors and direct drive hub motors (also known as gearless hub motors) in descriptions of e-bikes. Often the references mention the supposed pros and cons of each but seem to assume you actually know what the different terms mean. If you need a quick rundown of what these two different types of motor design are and which might suit you, then Electric Bike Report has you covered.

What’s the difference between direct-drive and geared hub motors on e-bikes?

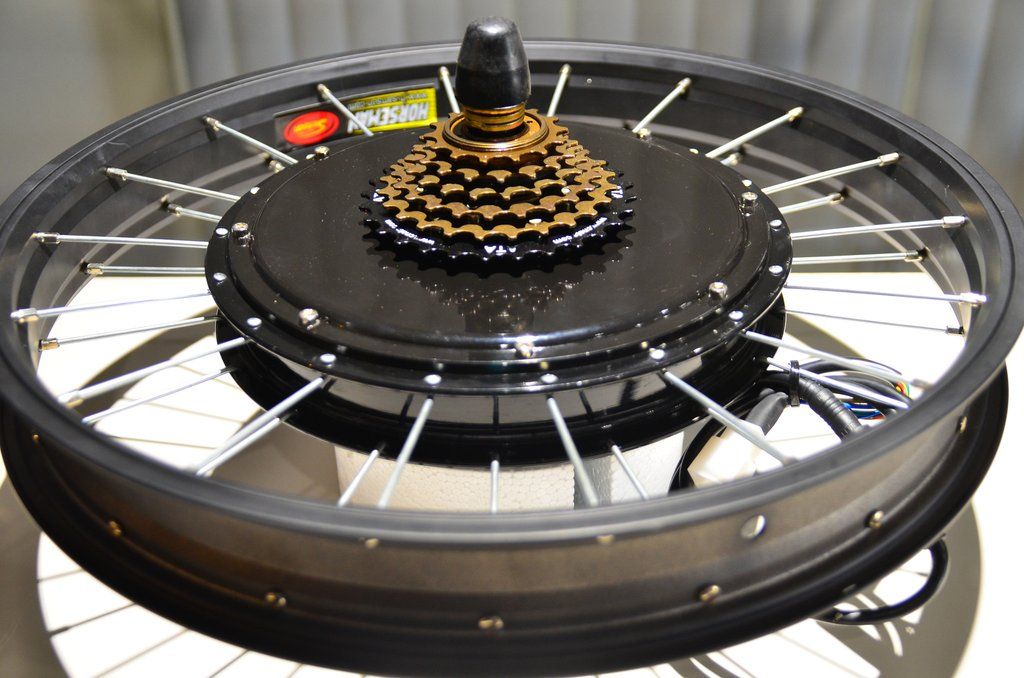

The terms geared and gearless refer to the way power is transferred from the motor to drive the bike forward. In practice, the distinction usually applies to hub motors (found in the center of the wheels) rather than mid-drives (found around the pedal cranks) – the vast majority of mid-drives are geared motors.

Geared hub motors overview

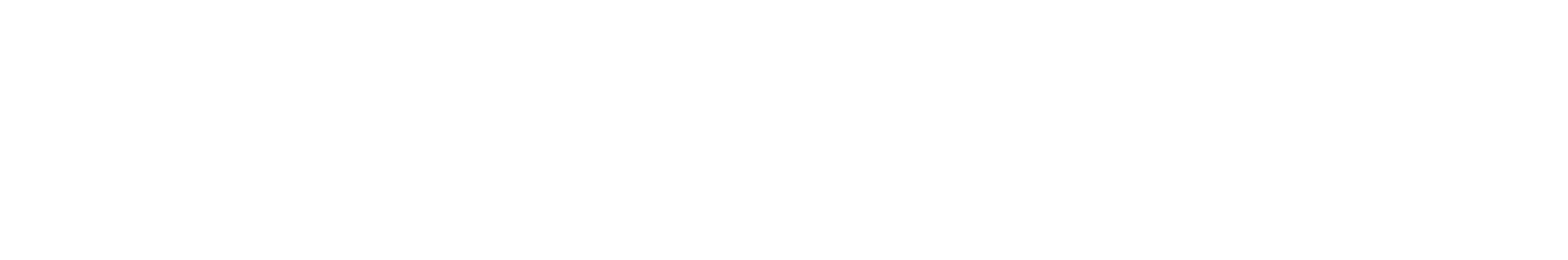

A geared hub motor uses a system of gears, within the hub itself, that transfer the turning force of the motor through to the hub and the wheel. It’s most easily seen in the above diagram typical of a budget hub motor. The central gear, fixed to the spinning motor, turns through a series of other gears (called epicyclic and annulus, but that’s not really important…) onto the wheel hub.

The main point to get across is that the gearing inside the hub reduces the fast speed the motor turns at to enable the wheel to turn at a more suitable speed. Motors like to turn at a fast speed, much faster than your bike wheel turns, hence the need for gearing. Geared hub motors are the commonest and most budget form of hub motors.

Gearless (direct drive) hub motors overview

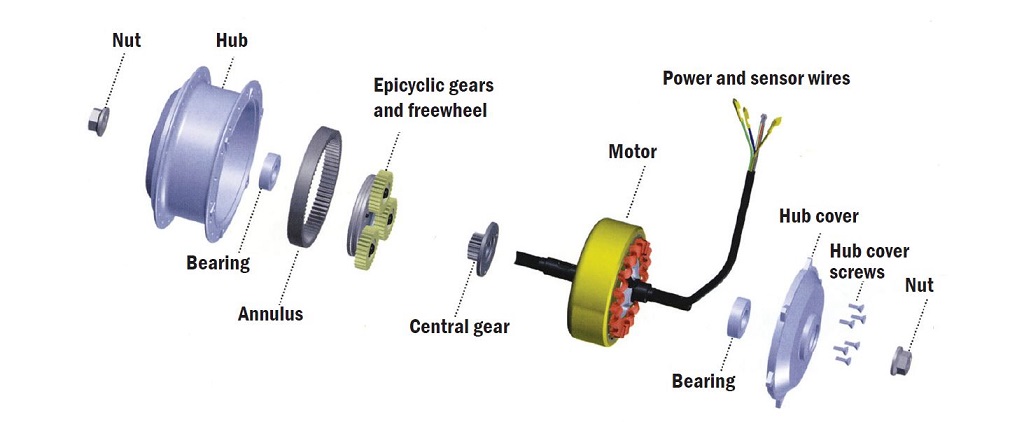

Yes, you guessed it, there are no gears within the wheel hub on gearless hub motors! As the image above shows, the wheel hub in a gearless system is the motor itself. The bunch of copper wires you see are part of the stator on the right. The stator becomes an electromagnet when the motor controller draws current from the battery into the wires. In the hub shell on the left, are the permanent magnets which the stator forces to turn when powered up, by cleverly attracting and repelling magnets at just the right time. No gearing involved – just magnetic forces – hence the gearless moniker.

Whilst this might sound the ideal solution – why introduce extra gearing into the hub if it’s not needed? – it’s not quite as simple as that, as we explain in the pros and cons section below.

Pros Of Geared Hub Motors

- Smaller and lighter than gearless – and in recent years they have been getting smaller and lighter. Gearing within the hub allows the motor power to be more effectively leveraged so geared hub motors are usually lighter and smaller than their gearless counterparts. Geared hub motors usually weigh between 2-4kg and are small in diameter, allowing them to remain pretty discrete on the bike.

- Geared hub motors are better for low-speed, high-torque applications and so are often found on class 1 and class 2 e-bikes that only need motor assistance to a maximum of 20mph. Their ability to generate high torque means they can be a better option for hill climbing (generally you have to go very large and heavy in gearless terms to generate similar torque).

- Most geared hub motors have a freewheel, meaning they are relatively easy to pedal when there is no electric assist

- Often cheaper to manufacture and so to buy compared to gearless systems

Cons Of Geared Hub Motors

- Some geared hub motors can be noisy, though many modern geared hub motors are pretty quiet as motor manufacturers have learned the advantages of new materials and designs such as helical patterned gearing. A test ride is really the only way to find out if the noise level of any particular geared hub motor is acceptable to you.

- Gears wear and may need replacing (though usually this takes at least a few thousand miles, with better quality motor gears going on and on for many thousands of miles). Still, as the gearing is small and designed to make a wheel spin fast, much heavier riders and riders with a lot of cargo may have trouble with long term durability, especially if the motor is regularly worked very hard up steep hills.

- Well-known manufacturers of geared hub motors include Bafang, Shengyi and Mahle (eBikemotion).

Pros of Direct Drive (Gearless) Hub Motors

- Virtually silent running due to the fact there is no gear noise

- Better for speed e-bikes, for example class 3, 28mph assisted e-bikes. Your pedal effort and the motor’s effort are transmitted to the road with two components: speed and ‘torque’, or turning force. As they have an inherent lack of torque (see ‘cons’ below) gearless motors perform better at speed where they can run more efficiently.

- Possibility of regenerative braking, being the ability to recharge the battery when the motor is used as an electronic brake. Whilst this sounds magical, in reality simple physics dictates you are likely to be disappointed with the actual amount of charge put back into the battery. Regenerative braking is much more effective on larger, heavier vehicles (such as electric trains) where energy losses are less, in proportion to the size of the vehicle.

- Still, regenerative braking can be a nice feature on very long downhills as it saves you having to constantly brake and can also stop excessive brake pad wear and help combat brake overheating. The latter can be a potential issue with very heavy e-bikes, such as e-cargo bikes, on long and steep downhills.

- Less moving ports compared to geared motors and so, mechanically speaking, less to go wrong. Still, you generally get what you pay for and, as the set of magnets fixed to the hub shell are essentially stuck on, they have been known to come unstuck on poorer quality motors or one ones worked very hard for a long period of time.

Cons Of Direct Drive (Gearless) Hub Motors

- An inherent disadvantage is that a gearless motor has to run at wheel speed, which may only be 200rpm with 26-inch wheels, or 300-400rpm on a small-wheeled bike. This is very slow for an electric motor and although careful design can allow a gearless hub motor to run quite efficiently at such a low speed the design is never likely to rival the low speed efficiency of geared hub motors where the motor can run at a higher speed.

- They lack torque which equates to ‘twisting force’ or the all important hill climbing ability.

- Usually large and heavy; they have to be, to overcome their inherent lack of torque in the gearless design. Hence gearless motors consume more energy to get them moving and to climb steep hills. They are typically between 4-9kg and over 20cm (8″) in diameter.

- Related to the above, they are less efficient and all other things being equal, will give less range than geared motors.

- Lack of a freewheel means harder to pedal when there is no electric assist

- Well-made ones with regenerative braking can be pricey

Good examples of high-quality gearless hub motors are Neodrives and the Syno and Cyro drives used on Stromer e-bikes.

Geared Hub Vs. Direct Drive Hub Motors: Which Is Best for You?

By now you’ve probably guessed that the answer is: “it depends.”

If keeping your bike relatively lightweight is appealing and if stealthiness, freewheeling and increased range trump longevity, then a geared motor is likely your best option.

If you’re expecting to rely much more heavily on the motor, craving a higher top speed (20+ mph), solid long-lasting value, and a quiet motor, then a super-beefy direct-drive may be best for you.

However, don’t forget that geared and gearless motors are similar in a lot of ways. They can both be set up to use cadence or torque sensing and / or throttle control. At the end of the day if you get a good quality hub motor on a good quality e-bike you will have a great experience.

There’s lots more info about specific hub motors at our Complete Guide to Hub Motors and our Guide to E-bike Conversion Kits.

Related

Reader Interactions

Trackbacks

-

[…] In my opinion, the first item you should decide on is the electric motor. Traditionally the hub motor has been the most popular choice for electric bikes. With the hub motor you have two choices, geared hub motors and direct drive motors. Each type has its own pros and cons which can be viewed here: https://electricbikereport.com/electric-bike-direct-drive-geared-hub-motors/ […]

-

[…] There are direct drive hub motors that use the whole hub shell as the electric motor. And there are geared hub motors that have a smaller internal motor with planetary gears that drive the hub shell. Here is a comparison of direct drive and geared hub motors. […]

-

[…] Yuba uses the BionX 350 watt direct drive rear hub motor. […]

-

[…] are well balanced. If keeping your bike relatively lightweight is appealing and if stealthiness, freewheeling and increased range trump longevity, then a geared motor is likely your best option. If you’re expecting to rely […]

-

[…] twice as small! If keeping your bike relatively lightweight is appealing and if stealthiness, freewheeling and increased range trump longevity, then a geared motor is likely your best option. If you’re expecting to rely […]

-

[…] But ultimately noise produced can vary from one bike to another, and increased stealth sometimes comes at the cost of torque, range, and additional weight. Nevertheless, when it comes to reducing noise there’s nothing better than a direct drive motor. These are some of the simplest electric bike motors available and yet they are still able to produce enough speed to commute around the city and enjoy the view without constantly being distracted by the sound. Direct drive motors tend to be preferred for speed, so it makes sense to use them on cruisers. A more detailed breakdown of the two different types of motors can be found here. […]

-

[…] tremendously, and came up with the idea of putting the engine in the wheel itself. By using a hub motor, he could power the wheel directly while reducing noise and vibration. “That was the turning […]

![]()

Source link