This is news, because General Motors is big, and they already have experience with hybrids and pure electric vehicles. Many others have added a few EV’s to their line-up, but occasionally it looked like they were only “green washing” their company for the PR. However…this initial order is for 500 full-sized delivery vans (with more to come), and that means it’s a big deal. So…let’s take a look.

_____________________________________________________

BrightDrop

GM’s new EV division is “BrightDrop“, and they have delivered the first five of these delivery vans to FedEx’s facility in Inglewood, California. They have announced that they are in the final stages of developing their Cadillac “Lyriq” EV, which is an upscale SUV. They have also announced that they will be reviving the “Hummer” as an AWD off-road EV. They have developed an EV Silverado pick-up to be shown in January 2022 at CES in Las Vegas, where CEO Barra is scheduled to be the keynote speaker. The Silverado is rumored to have an option for a 400-mile extended range battery pack.

_____________________________________________________

GM’s Ultium EV line

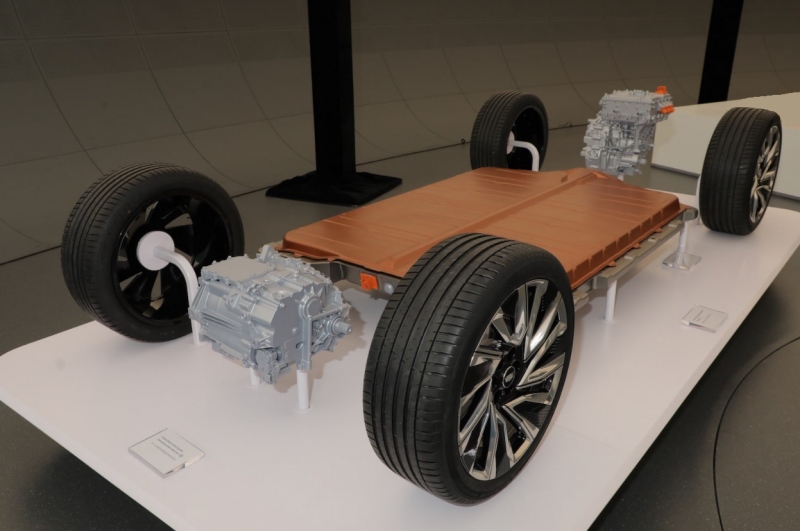

The specific model that FedEx chose is the EV600 cargo van, with 600 cubic feet of cargo space. uses their “Ultium” line of EV components, which have taken a while to develop, because GM wants them to be useable as a global platform, and to be configurable in a variety of ways for different vehicles.

In the pic above, the platform FedEx chose for the first few EV600 delivery vans is an AWD system, and the short motor module is the rear of the van, with the taller unit in front. BrightDrop also has an option for a FWD version of the EV600.

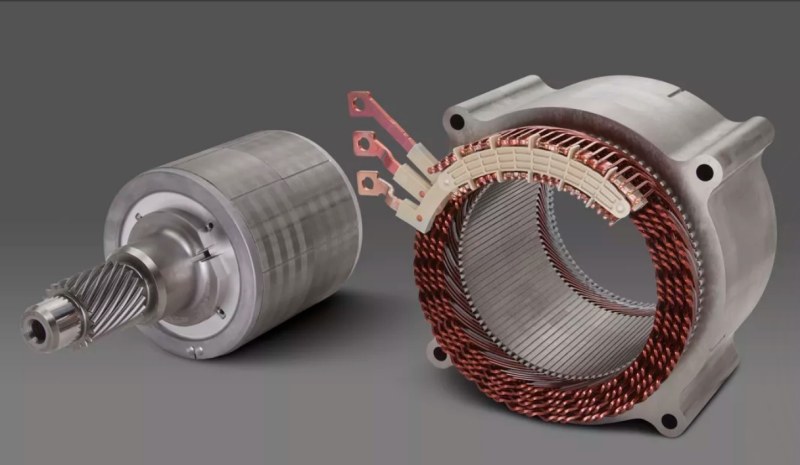

GM has designed several sizes of it’s Ultium motor, using the same radial-flux inrunner topology. The stator uses “bar wound” windings, which has also been called a “hairpin” winding. This style is easier to automate it’s manufacture and assembly, and the thickness of the wire shows that GM plans to lean the motor’s duty-cycle towards using high amps as a temporary peak for acceleration and torque.

Not shown in the pic above is that the rotor on the left is using the Interior Permanent Magnet / IPM mounting. By embedding the magnets slightly below the surface of the rotor, and farther away from the air-gap…the power remains the same, but the magnets can run cooler, because they experience fewer magnetic eddy currents than a common surface-mounted magnet arrangement.

The motors are currently being manufactured at GM’s Baltimore facility.

_____________________________________________________

The Ultium Battery

GM has revealed that their Ultium line of products will be using a flat pouch cell, developed by a team that was led by Andy Oury. Their battery chemistry was created in partnership with LG in South Korea, and has resulted in using more nickel, but…using about 70% less cobalt. Cobalt is expensive, so creating a new battery formula that uses much less of it brings the cost down. Cobalt is also very politically sensitive, because the few countries that produce it right now have employed horrific mining practices. As a result, several companies have developed recycling processes to successfully reclaim the cobalt from used batteries (for more info on this, read our article by clicking here).

GM has announced a strategic collaboration with Controlled Thermal Resources (CTR) to secure lithium from Southern California’s Salton Sea. GM’s current Ultium battery cells are being manufactured at their facility in Lordstown Ohio, in a partnership with Solid Energy Systems (SES), with a second facility being built in Spring Hill, Tennessee.

SES is a new company that arose from the ashes of the famous but now-defunct “A123” company.

GM is claiming that this battery pack has the option of an integrated series/parallel switching so it can be charged at 400V in the US, and at 800V in Europe, and that’s interesting. It’s not technically difficult, but this is the first system I know of that is attempting to add this feature (You can read our article on EV formats and voltages by clicking here)

The charge plug is a J1772 format (shown below). The 5-pin section on the top half is for efficient AC charging that will likely be used to fully charge the battery when they are parked late at night, when the electric grid has lots of excess capacity, and charging rates are low.

The two large pins in the bottom half are for high-amp “fast charging” which is likely to be used whenever the van returns to the logistics center to get a quick re-load of cargo, and go right back out again. The max range is listed as 250-miles, but that would be under ideal conditions, but even so…this van is likely to be able to easily reach 200 miles in the real world, which poses no problem with a little battery top-off every time it makes another round.

I suspect the weight of the van and it’s stop-and-go city user-profile will allow it to harvest a significant amount of regenerative braking (regen). Electric bikes have a tiny tire-patch in contact with the pavement, and are relatively light, which limits how much regen can be dialed-in before causing the tires to skid. Vehicles with high-regen can have their standard brakes last many times longer than they do in a gasoline car.

_____________________________________________________

This is good news, because when a company as big as General Motors dives into EV’s with both feet, there is a ripple effect in research and development, and anything that succeeds will drive competition. Tesla has been grabbing most of the EV news this last decade, and even Ford has generated a little buzz, but…this time I think GM is serious about producing EV’s for a broader market.

_____________________________________________________

Written by Ron/spinningmagnets, December 2021

Source link