I’ve always liked the style of vintage vehicles, and there is a growing trend of converting old gassers to an electric drivetrain. Jim in Virginia has done a beautiful job, and fortunately for us he took lots of pictures.

_______________________________________________

Piaggio Vespa PX 125

I have read of projects many times where the builder bought a running used vehicle, and then sold the engine and transmission for close to the price of the whole purchase. Most of the time, if you find a good deal on something, then the engine will have a lot of miles and be barely running, if it runs at all.

Worn cylinders and piston-rings create low compression, and also oil blow-by. This fouls the plugs and makes the exhaust smokey. With worn tires and brakes, old scooters like this can be found dirt cheap.

Vespa is Italian for “Wasp”, and it was designed by Piaggio & Co in Pontedera Italy, with production starting in 1946. After WWII, Italy was in shambles, and most people could not afford a car. The nimble Vespa was stylish, but it’s main benefit was that it was cheap and provided excellent fuel economy with it’s simple air-cooled 98cc one-cylinder engine.

The rear swingarm only uses one shock absorber, and the front fork only has an arm on one side…also with only one shock. The body panels cover the wiring for a sleek appearance, and it has a surprising amount of lockable storage.

There are two distinctive features that are worthy of mentioning. First, it has an open leg bay instead of a “top bar” that you might expect from most types of motorcycles. I have heard in the past that this made it easier for women to ride these when they were wearing a dress, but a deeper dig revealed the original designers felt the open bay would reduce leg injuries when a car hit the scooter from the side.

The second thing that stands out is that the deluxe models had an electric starter as well as a type of “automatic” transmission, which do not require the rider to operate a clutch. These things made them very easy for anyone to learn how to ride safely in a very short amount of time (Jim’s had a clutch and a 4-speed conventional transmission)

The engine, clutch, and transmission are built around the rear wheel, so…there is no external chain, which eliminates the common oiling and adjustment of any chain as it wears. Since the finned air-cooled engine is fully enclosed, it has a shaft-mounted fan to blow air onto it (part number 7), and this design has worked well for many decades. The body panels covering the engine also made it run quieter, which made it feel more civilized.

In WW-One, Piaggio went from being a lumber yard to producing parts for wooden airplane frames. During WWII, Piaggio was pressed into service by the Italian government to produce modern aircraft parts. As a result, the Vespa was designed by aircraft engineers, resulting in it’s innovative rounded shape, which was not only considered aerodynamic, but it was also visually appealing. The distinctive large curved splash-guard on the front was very innovative at the time, and much appreciated by riders when it rained.

Another feature used by the aircraft engineers was a monocoque construction. This is where the frame is made from curved sheetmetal sections that are riveted and spot-welded together, rather than having a separate frame and body. Doing this made the Vespa lighter and less expensive. Both are good features, but…because of this, rust can be fatal to a restoration due to how difficult it is to repair properly. You can’t just take the sheet-metal on an old Vespa body and make it pretty, it must be repaired strong enough to support all the stresses of a vehicle frame.

The biggest sales promo for the Vespa was Hollywood. In 1952, Gregory Peck and Audrey Hepburn rode through Rome on a Vespa in the hit romantic movie “Roman Holiday”. Sales figures showed an immediate and significant up-tick in global Vespa sales volume.

Millions of Vespa’s have been sold over the decades, and Piaggio continues to produce a classic version. However, they also have developed their MP3 3-wheeled high-performance scooter, and in 2014, they developed a mid-drive electric bicycle.

_______________________________________________

Tear-Down and Cleaning

Once Jim had the Vespa in his garage, he researched which hubmotor and controller he thought would work well, and then ordered them. While he waited for those to arrive, it was time to get busy tearing everything down, and cleaning up all the parts.

In the pic above, you can clearly see how the Vespa does not have a conventional separate frame. The central square tube on the floor-boards is all hollow sheet-metal.

Jim chose a Quan Shun 205 / 50H hub motor, rated for 4000W at 72V, specifying a model that accepts 10-inch tires. QS has been making electric motorcycles in China for many years, and we featured them in a large hubmotor index back in 2015

In the pic above, Jim has mounted the disc brake caliper bracket and shimmed it to a perfect location before welding it on. The stock Vespa drive does not stress the wheel axle, so swapping to a powerful hub-motor requires a very strong frame drop-out to be added, and Jim has also included a beefy pinch-bolt to both sides.

_______________________________________________

Paint

Painting seems to attract dust by electro-static fields generated in the air. The DIY solution is a HEPA air filter and a portable booth in your garage. $65 from Amazon.

_______________________________________________

Re-Assembly

The tear-down, cleaning, repair, and painting phases are often filled with unexpected surprises, but hopefully when you get to this point, the re-assembly goes smoothly, and it is definitely the exciting part.

For charging, he chose an XT90 connector set, but for the power from the battery to the controller, he is using beefy polarized Anderson PP180 connectors.

Kelly KBL96251, 24V-96V, 250A, BLDC Controller/with Regen

HWZ-9612 Series DC/DC Converter 48V-130V to 12V @25A

Emergency cut-off Contactor KEMG-250A, with an additional 250A breaker

In the pic above, you can see that JIm cut a rectangular hole in the top of the glove-box to mount an electrical system dashboard.

Light Emitting Diodes (LED’s) can provide the same amount of light, while drawing much less energy from the battery (compared to an old-style filament bulb). A gasoline-powered Vespa has an alternator to generate electricity, but an electric Vespa needs to save as much energy as possible to extend the battery range.

_______________________________________________

Battery

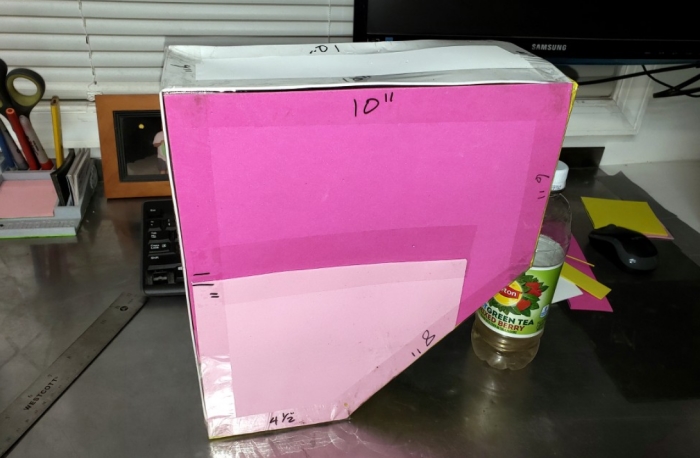

After some research, Jim decided to go with a 72V system, provided by a battery pack using 20 lithium cells in series (20S). In the pic below, he mocked-up a box that shows the largest shape that can fit inside the stock under-seat compartment.

Performance-wise, a frame-mounted motor would be ideal for the suspension, when hitting potholes in the street. However, scooters don’t have anywhere to mount a motor on the frame without significantly intruding into the only realistic area to put a battery pack.

For this reason, I’m still seeing builds for low-speed street use that use hub-motors, since it simplifies the layout for home builders, and allows a monolithic block shape for a large single battery.

Below is the custom-ordered 72V / 20S battery made from 2170-format cells, and the size ended up being 38-Ah.

Jim has a wonderful garage that is perfect for tinkering with a winter project.

A few small Generic Chinese scooters have embraced the vintage style, but you can tell they don’t quite capture the beauty of an authentic full-sized Vespa.

Jim took a LOT of pictures (which is fortunate for us), and he detailed the process of this build in a forum discussion. For more details click here.

Below is a retro-vintage sign Jim found. I love this style!

_______________________________________________

Performance

This conversion easily leaps up to 50-MPH, and on flat land with no wind, he even reached 60-MPH. The zero-to 50-MPH is where electric drive really shines because motors have full torque available from the first RPM’s.

In stop-and-go city traffic, Jim went from a 94% charge to 38% in 57 minutes, reaching a distance of 24 miles (average speed over the course of the run was 27-MPH while keeping up with traffic).

The bike weighs 210 pounds, the rider weighs 275…

Lithium batteries have a fairly flat discharge curve, so getting 24 miles from 56% of the battery pack means we can “estimate” his 72V 38-Ah pack can provide roughly 2.3% of the battery per mile, or…43 miles taking a full battery down to a completely discharged pack.

_______________________________________________

Written by Ron/spinningmagnets, March 2021