If you are tired of seeing clickbait titles about some new battery chemistry, I actually want to tell you that there will be no huge sudden change, except for the upgrades I recently wrote about. A few months ago in July, we wrote about how nearly everyone is adding silicon to the anodes of lithium batteries (to see that, click here), because it dramatically improves the speed that the battery can be charged at, and it also increases the energy density of those same batteries.

Just before that in June, we wrote about how the Chinese company CATL was now the largest battery company in the world, and the Chinese government had spent $23 Billion dollars to develop every new battery advancement that might be possible (to see that article, click here).

While researching the information for those articles, I kept seeing articles and youtubes about sodium and sulfur batteries, and today I’m writing about what I’ve learned about these new chemistries, and how they compare to the Lithium-based batteries we have been using for the last 20 years.

___________________________________________________

Lithium Supplies

Ten years ago, there was quite a bit of talk about how the world needed hundreds of millions of electric vehicles, and the known lithium supplies might not be enough. The first step was building-up a recycling network, and we wrote about that back in March of 2021 (to see that article, click here). And it wasn’t just recycling Lithium, because the world’s supplies of nickel and cobalt were an obvious bottleneck to production, so recycling those two was especially important.

However…once everyone started looking for more reserves of lithium, they FOUND them! One of the fears concerning the materials needed to produce batteries, was that a trade-war and embargo could disrupt supplies. There’s a place called Thacker Pass in Northern Nevada that is the most recent significant find. I’m adding this map below to show that the North American NAFTA region is no longer in any danger of having lithium supplies restricted by global politics.

The “M” in the NCM chemistry is for Manganese, and that element has always been one of the most common elements on Earth, so that was never a concern.

___________________________________________________

Sodium Batteries

Sodium batteries exist right now, and BYD in China is selling the base model of the “Seagull” with a sodium battery (to see that article, click here). The major benefit of that sodium battery is that its is less expensive than lithium, and low price is the main feature of the BYD Seagull.

Sodium batteries do have other benefits. Sodium is very abundant and widespread, so supplies are not a limiting factor. “Northvolt” is a Swedish company that developed a sodium chemistry that uses no cobalt or nickel, and their particular chemistry also adds some aluminum, Iron and manganese, which again, are cheap and abundant.

Another major player in the sodium battery club is Natron Energy in Santa Clara, California. They have recently broken ground on a new $1.4-Billion sodium battery plant in North Carolina. According to Natron, their sodium chemistry is non-flammable and won’t catch fire or explode even if punctured or heated.

However!…Even though the BYD Seagull is an EV that’s actually using sodium cells (along with forklifts, and data-center backup batteries), I believe the biggest market for sodium cells is the solar-to-grid storage due to their low-cost per energy, and also because they can provide many more years of cycles than lithium-Ion. It’s a booming market, and also, the other chemistries still provide more miles of range per volume, so when it comes to vehicles…lithium still looks good.

As a side-note, military contractors have found that Natrons sodium batteries perform well in a wide temperature range, from 0-45°C (32–113°F).

___________________________________________________

Sulfur Batteries

Forty years ago, lithium, silicon, sodium, and sulfur were all identified as elements that had the best potential to make a great rechargeable battery. Its only random luck that Lithium-Ion was the first chemistry to have a breakthrough and work well enough to grow the EV movement we are in right now.

Sulfur is cheap and abundant, and if you happen to buy a barrel full of sulfur this week (as one might do on occasion), there’s a high likelihood that it was separated out of crude oil to make ultra-low-sulfur-diesel fuel (ULSD), with the extracted sulfur being a waste-product. Sulfur is also commonly famous as the smell of rotten eggs.

A lot of smart people have also been working on sulfur-based batteries, and a quick Google shows that there are at least ten big companies investing heavily in this for reasons I’ll list below. One company I’d like to spotlight is Lyten in San Jose, California. Their batteries are mature enough that they have contracted to supply the next generation of EV cells to Stellantis, which is a global corporation that owns 14 car brands, including Chrysler, Dodge, Jeep, and Fiat.

After a few years and many millions of dollars of experimentation, sulfur batteries have finally had their secrets uncovered, and all the major players seem to agree that combining some lithium into the sulfur has fixed many of the problems that had been found when using sulfur alone. As with the previously-mentioned chemistries, Lithium-Sulfur (Li-S) batteries use no cobalt or nickel, so there is no material limit to how many can be made.

The one area where Li-S batteries really shine is in their weight per energy. EV cars have mainly been concerned with energy per volume, because the size of the pack was the limiting factor in having a good amount of range. The result was that EV batteries have been very heavy, but they still sold well because having 300 miles of range was considered very desirable. Li-S batteries will change that, and soon, a 300-mile battery pack will no longer need to be so heavy.

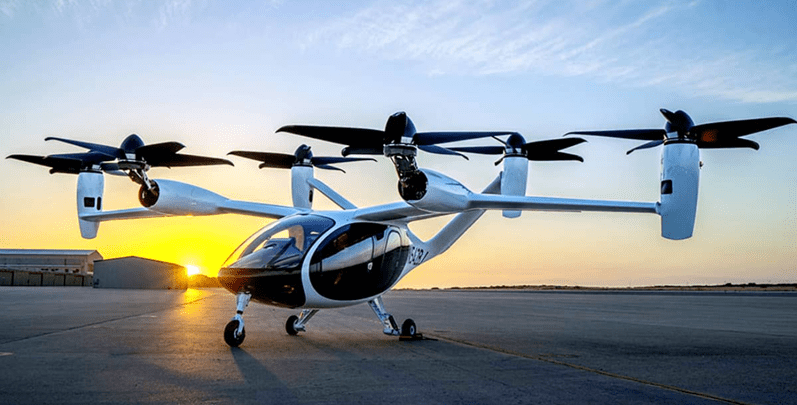

However, I don’t think that cars are where Li-S will have its greatest impact. Back in March of 2024, we wrote about some recent electric aircraftand the driving characteristic for aircraft is energy per weight of battery. A lithium battery of the same volume would be heavier than a Li-S battery in spite of the lithium’s long range, but…if you shrunk the lithium packs size down to be the same weight as the Li-S, then the Li-S battery would have more range than the Lithium-Ion. For aircraft, the cargo and fuel are measured by their weight.

Speaking of aircraft, there is no reason that every battery couldn’t use the patented polymer/graphene electrodes from “StoreDot” to replace the aluminum and copper ribbon electrodes we have all been using for the last twenty years, but I couldn’t help but notice that…they are not only cheaper, they are lighter than aluminum and copper electrodes. I believe the early adopters will pay a premium to use these in electric aircraft batteries, where every ounce will count.

___________________________________________________

Lithium-Iron-Phosphate / LiFePO4 / LFP

I want to make sure to give a shout out to an old favorite. As I stated in our article on the Chinese battery company CATL…about ten years ago, China decided to make an enormous investment in alternative vehicles. Since the battery packs on an EV can be as much as seven times bigger than a hybrid battery, their first push was to manufacture a LOT of hybrid cars, and since these hybrids had a small gasoline engine as a range-extender, the battery packs did not need to have the absolute maximum range per volume.

As a result, most of them used the LiFePO4 chemistry because of its two famous characteristics compared to lithium-Ion packs like those found in the early Tesla’s and the Nissan Leaf. First, LiFePO4 is inherently more fire-resistant than lithium-ion, because it must heat up to 190°C (375°F) before it begins converting to a gas, and even then, that gas is not combustible. Lithium-Ion packs have had more range per volume than LiFePO4, but they can begin off-gassing at lower temp of 130°C, and that flammable gas composition can lead to a thermal runaway of the entire pack.

The second commonly-known benefit of LiFePO4 is that it has been known to last twice as many cycles and years as Lithium-Ion. And of course, it has never had any cobalt or nickel from the beginning.

One of the great news items I found recently is that for the last ten years, liFePO4 is one of the things that China has continued to improve, and now they have doubled its range per volume, and also found a way for it to be fast-charged at a very high rate.

___________________________________________________

Cordless Tools and Drones

I have seen cordless tools that are using the 2170 format cells with the “tabless” design. I would have called that an “all tab” design, because the entire edge of the rolled-up cell material is the “tab”, which eliminates a common bottleneck to current, and a common hot-spot. Without considering any changes to the chemistry at all, the mechanical change of the tabless design allows cells to provide exceptionally high current, with less interior heat.

The interior heat of normal operations is so reduced, that the size of the cell can be increased, and that is why Tesla was able to go from the 2170 cell to the larger 4680 cell, which I am a big fan of.

And, as far as drones are concerned, anyone who has been watching the news has seen how several nations have dramatically increased the use of drones in combat. The larger ones still use jet engines and propellers driven by engines. However, there are many situations where an electric drone is useful. When flown at night, they have no hot exhaust, and that means they are MUCH harder to spot when using a thermal imaging sight.

That being said, the military has shown in the past that they will pay extra to get high performance, and whether the king of the hill ends up being LiFePO4, Lithium-Ion, or lithium-sulfur…they will fund the early production examples.

___________________________________________________

Let’s wrap it up

From where I’m sitting this is all good news. Except for solid-state batteries. Those have taken a long time to develop, and the end result is not as good as promised, AND…the new “semi-solid” batteries have surpassed the SSB’s promised performance.

Between lithium recycling and the new lithium reserve discoveries, we no longer have to worry about a lithium battery shortage. Silicon, sodium, and sulfur are all now bearing fruit, so the next-gen of batteries will be cheaper, have longer range, and will charge-up much faster. Not only will the batteries be cheaper, but they should last at least twice as many years as we expect them to last now.

The Car at the header of this article is the very popular Xiaomi SU7 from China. If you could buy one in China with no tariffs, it would be about $30,000 and it has a 500-mile range.

The world has quite a few problems right now, but having better batteries available is something that may provide a new tool to tackle some of those problems, and that’s a good thing.

___________________________________________________

Written by Ron/spinningmagnets, September 2024

.

.

.

#Sulfur #Sodium #batteries #Lithium #King #Cars

Source link